Hinged EI260-C fire doors for freezer rooms

Door System has developed a new single-leaf hinged EI260-C fire door for freezer rooms. The fire door is manufactured in Denmark and has been tested by the Danish Institute of Fire and Security Technology (DBI).

The door passed the critical time limits of 1 hour and then 1 hour and 8 minutes, giving it a more comprehensive range of applications.

Extra large size

The EI260-C fire door for freezer rooms was tested with a wall opening of 1460 x 2550 mm (clear opening 1220 x 2430 mm). Since the door lasted for more than 68 minutes, we will have the possibility to deliver the door in a size larger than the tested door and supply the door with more options. We will know when we receive the final test report from DBI.

Safety has been in focus

The new fire door has been developed with a brand-new heated exterior handle and interior pushbar, both of which provide a high level of safety for the door solution.

To prevent condensation, the fire door is fitted with heating wires on the door leaf and in the frame. Furthermore, the door has been tested with our standard freezer room seals, so the door provides optimal sealing and insulation.

The door is available in stainless steel and galvanised versions and can be supplied as a self-closing freezer room fire door. The door has elevating hinges, that lifts the door free of the floor.

Installation in heavy firewalls

The EI260-C fire door is approved for installation in a heavy fire wall with the option of using freezer room elements without the risk of thermal bridges. It has been also tested and approved to be placed at height.

Also approved installed in plaster board and panel wall

We have performed (and had approved) an additional test of our new freezer room fire door installed in plaster board and panel wall, and with a new frame solution for the panel wall.

As always, the new tests were carried out at DBI - The Danish Institute of Fire and Security Technology.

Contact us to learn more about the options with the new EI260-C fire door for freezer rooms. Feel free to use the form below.

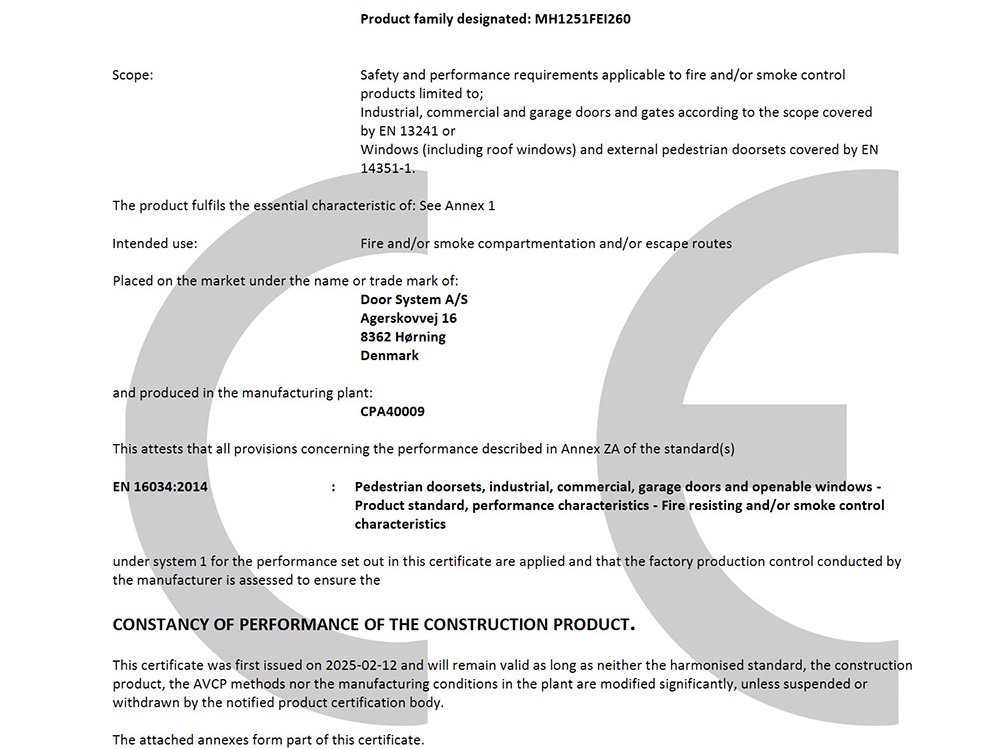

When it comes to fire safety, there is a meticulous process before the CE mark can be put on the fire door.

When we developed our new 1-hinged freezer room fire door in late 2023, we started an extensive test programme in collaboration with The Danish Institute of Fire and Security Technology (DBI).

The freezer room fire door had to be tested and approved according to the European standard EN 16034 before the CE mark could be put on the door.

The test process

As part of the approval process, DBI visited Door System before the actual fire test to monitor and approve the production of the freezer room fire door to be tested.

“In December 2023, we had the first test of the freezer room fire door at the Danish Institute of Fire and Security Technology (DBI), where it was approved for installing in heavy fire walls. The fire door passed the crucial time limits of initially 1 hour and then 1 hour and 8 minutes, giving it multiple application options. The last few minutes are critical in this context,” says Brita Rosenbech, technical manager at Door System.

In early 2024, we received the test report from DBI on the freezer room fire door installed in a heavy fire wall. However, we wanted to test the fire door in several types of walls.

In April 2024, two additional tests were performed (and approved) on the freezer room fire door, this time installed in a plasterboard wall and a panel wall and with a new frame solution for the panel wall.

We then received the final test reports from DBI on the freezer room fire door, which was approved for installing in three types of fire walls.

Based on the test reports, an EXAP (Extended Application Report) was prepared in collaboration with DBI and Door System. The EXAP allows us to fulfil several customer requirements for the freezer room fire door, which includes height, width, doorstep, door switch, extra heating cables in the frame, installation of a kick plate, etc.

On the basis of the EXAP, DBI prepared the so-called classification report in the autumn, which is the documentation for the approval of the freezer room fire door and describes in detail what it is approved for.

DBI Certification checks the production processes

In November 2024, we had the annual audit for DBI Certification, which reviews and checks our fire door production processes.

Among other things, the inspection must ensure that employees’ knowledge is up-to-date and that the requirements for traceability, control and documentation according to EN 16034 are met in all processes related to the production fire doors.

The so-called FPC (Factory Production Control) must be approved once a year to ensure the consistency of our high-quality products, and it helps keep us sharp at the company.

CPR certificate and CE mark

In February this year, we received the CPR certificate for the freezer room fire door, which, together with the classification report, means that we can put the CE mark on the freezer room fire door. The CPR certificate is proof that the company has been audited and approved.

“It’s reassuring to know that a lot goes into meeting fire requirements and ensuring a high level of fire safety – it’s all about personal safety,” concludes Brita Rosenbech.

Learn more about our certificates, approvals and documentation for fire doors – click here.

If you would like more information or have any questions, you are welcome to contact our Technical Manager, Brita Rosenbech, by phone at +45 42 14 52 04 or e-mail [email protected].

Download

DoorSystem-datasheet-fire-doors-fire-sliding-doors-ENG.pdf80 KB

Data sheet for Door System fire doors and fire sliding doors

DoorSystem-fire-doors-freezer-rooms-Certificate-2531-CPR-CDB10026.pdf276 KB

Certifikat for Door System frostrumsbranddøre godkendt iht. EN 16034

DoorSystem-fire-doors-freezer-rooms-Classification-report-extract.pdf82 KB

Uddrag af klassifikationsrapport for Door System frostrumsbranddøre

DoorSystem-operations-maintenance-hinged-doors.pdf2 MB

Operations and maintenance manual for Door System automatic and manual hinged doors

DoorSystem-profile-brochure.pdf604 KB

Read more about Door System A/S